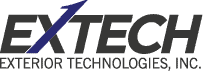

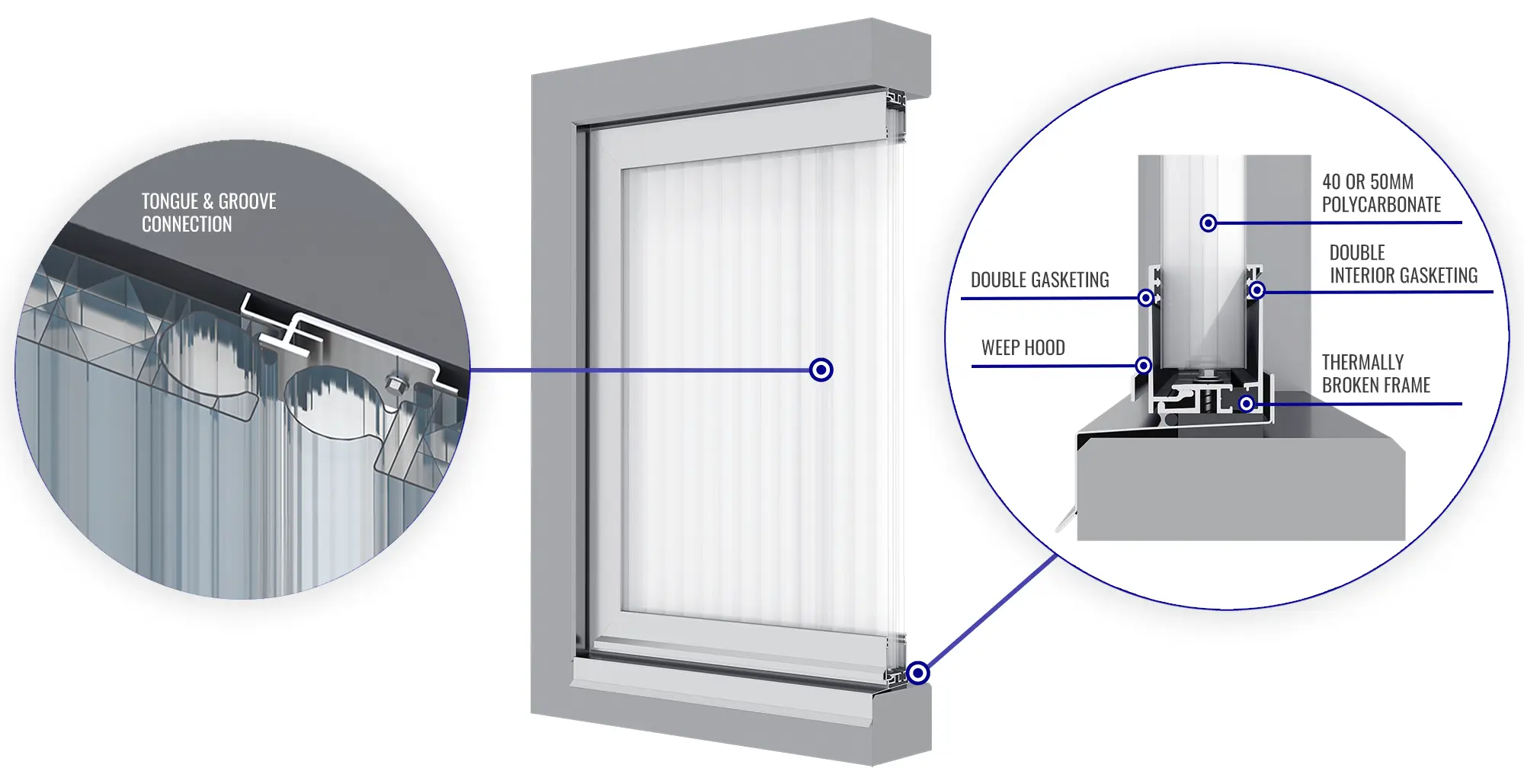

Elevate your building performance with the LIGHTWALL 3440®. Featuring both 40 and 50mm polycarbonate thick 'tongue & groove' panels, this system provides a simple installation and overall smooth appearance. Our LIGHTWALL 3440® system is unique in many ways and can extend up to 54 feet vertically.

-

UNIQUE FEATURES

- Double gasketed interior and exterior perimeter framing

- Aluminum glazing clips (typically fastened to interior horizontal supports)

- Optional thermally broken frame

- Deep rabbets for thermal expansion

- Weep hood to prevent water infiltration

GLAZING DETAILS

- 500mm (19-11/16”) wide tongue and groove cellular polycarbonate

- [0.28 U-factor, R 3.57] for 40mm panels (clear/opal)*

- [.19 U-factor, R-5.26] for 50mm panels (clear/opal)*

- Available in various colors and translucencies, with IR or AR coating options

- Co-extruded with a UV resistant layer

*Please contact us for performance testing for specific panel types. Values may vary based on panel color, finish (IR/AR/Matte, etc.), and polycarbonate manufacturer.

TYPICAL APPLICATIONS

- Schools

- Office buildings

- Recreational facilities

- Government buildings

- Aircraft hangars

- Military buildings

- Commercial buildings

- Interior backlit walls

- And more...

LIGHTWALL 3440® CASE STUDIES

Click an image to read more about our latest projects

SYSTEM DOWNLOADS

PERFORMANCE

Flammability Testing

Self-ignition: ASTMD-1929

Smoke Density: ASTM D-2843

Burn Extent: ASTM D-635

Interior Flame Spread: ASTM E-84

Weathering

Color Change: ASTM D-2244

Yellowing Index: ASTM D-1925

Light Transmission: ASTM D-1003

Miscellaneous

Air Infiltration: ASTM E-283

Water Infiltration: ASTM E-331

Load Bearing Capability: E-330

U-Value: NFRC

* Click on the icon above to view additional 3D scenes.

icon above to view additional 3D scenes.

LIGHTWALL 3440® OPTIONAL ACCESSORIES

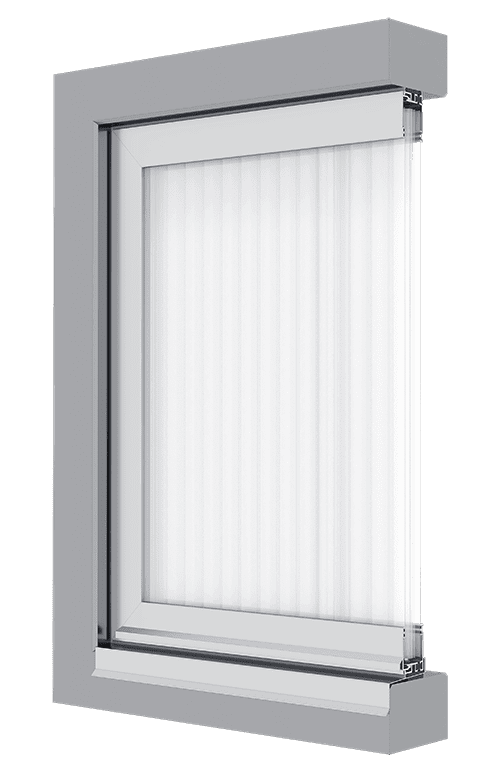

STRONGSPAN

Embedded at the tongue and groove connection, STRONGSPAN integrates with this system to extend spanning capabilities.

POLYCARBONATE CORNERS

For a sleek and continuous appearance to your translucent wall system, polycarbonate corners are available to elevate your next project.